Design and Fabrication of Mini Hydraulic Jacks

Introduction

In the realm of mechanical engineering and DIY projects, hydraulic systems often take center stage. One such fascinating innovation is the mini hydraulic jack, a compact yet powerful device capable of lifting weights that belie its size. This article delves into the mechanics and benefits of designing and fabricating a mini hydraulic jack.

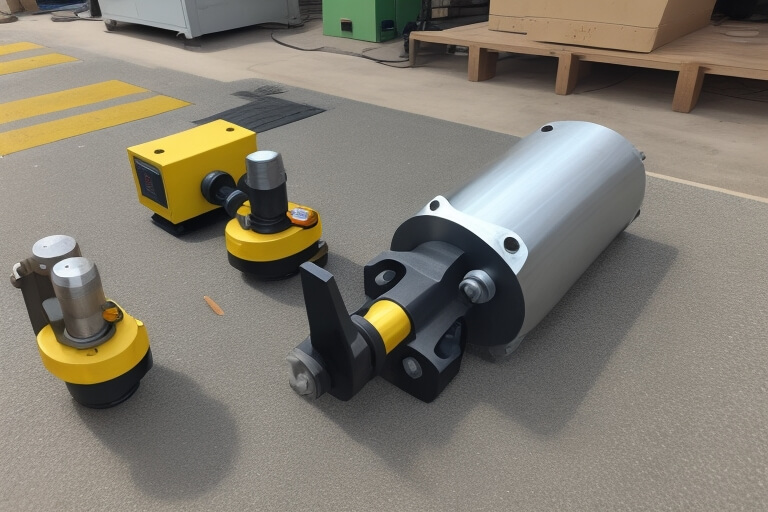

Key Components:

Parts:

- Syringe (Hydraulic Fluid Container)

- Pipe (Fluid Transfer)

- Lifting Frame (Mechanism)

- Bed (Load-Bearing Surface)

- Supporting Frame (Stability)

- Joints & Screws (Assembly)

The Working Mechanism

The heart of this mini hydraulic jack is a syringe, which acts as the container for the hydraulic fluid. Attached to the syringe is a pipe that enables the fluid to flow, powering the lifting frame. The bed, mounted atop the lifting frame, serves as the platform on which the object to be lifted is placed.

Advantages of the Mini Hydraulic Jack:

- Efficient Lifting: Despite its small size, this mini hydraulic jack is a force to be reckoned with. It can lift weights that are impressive relative to its dimensions.

- Easy Operation: The simplicity of the hydraulic system ensures that operating the jack is a straightforward process.

Conclusion

The mini hydraulic jack proves that size isn’t everything. With its efficient lifting capacity and ease of operation, it is a remarkable piece of engineering that can be utilized in various applications, from car repairs to warehouse tasks. Whether you are an engineering student looking to experiment with hydraulic projects or a professional in need of a compact lifting solution, the mini hydraulic jack is worth your attention.

In order to download the PDF, You must follow on Youtube. Once done, Click on Submit

Follow On YoutubeSubscribed? Click on Confirm

Download Design and Fabrication of Mini Hydraulic Jacks PDF