Manual Roller Bending Machine

Introduction

The manual roller bending machine has long been a staple in various industries requiring the bending of pipes and rods. This article delves into the design, fabrication, and functionality of manual sheet rolling machines, focusing on their key components and advantages.

Design and Fabrication

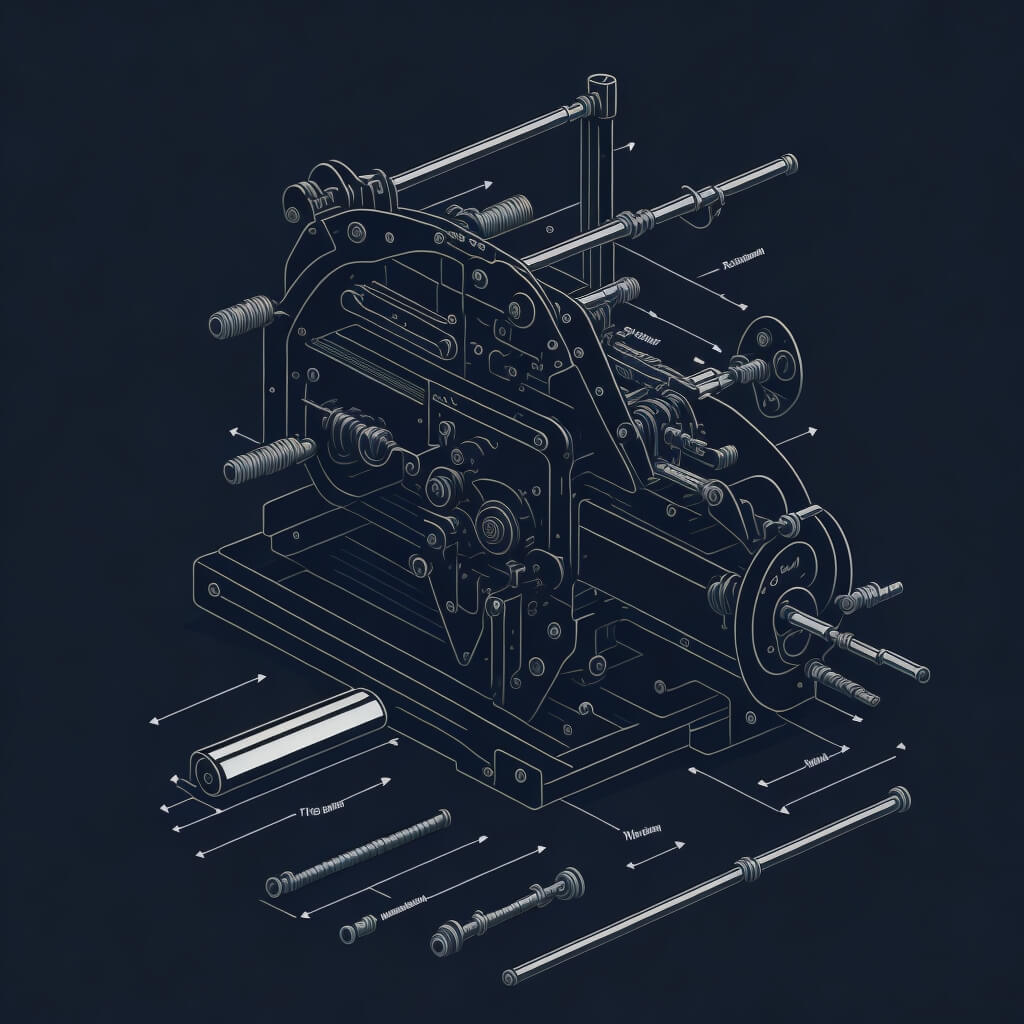

The manual rolling machine is ingeniously designed with a supporting frame that houses the roller mechanism. This mechanism is pivotal for the bending process and is driven by a hand-operated spindle wheel. The spindle wheel is connected to another roller via a chain sprocket mechanism, ensuring synchronized movement.

Key Components

- Bending Rollers: These are the core elements that perform the bending action.

- Flywheel: Aids in maintaining the momentum of the rollers.

- Bearings: Ensures smooth motion of the rollers.

- Housings: Encloses the bearings and other moving parts.

- Screw Mechanism: Allows for the adjustment of the bending angle.

- Moving Roller: Central roller that can be adjusted for different bending angles.

- Supporting Frame: Provides structural integrity to the machine.

- Mounts, Joints & Screws: These are used for assembling the various components.

Advantages

- Versatility: Supports a variety of soft metals.

- Ease of Use: The manual machine is user-friendly, making it easy to create curved parts.

- Cost-Effectiveness: Being manual, it is more affordable than its automated counterparts.

Conclusion

The manual roller bending machine is an indispensable tool for anyone involved in fabrication. Its unique design, coupled with its cost-effectiveness, makes it a go-to choice for bending operations. Understanding the bending machine parts and functions can significantly enhance your operational efficiency.

In order to download the PDF, You must follow on Youtube. Once done, Click on Submit

Follow On YoutubeSubscribed? Click on Confirm

Download Manual Roller Bending Machine PDF