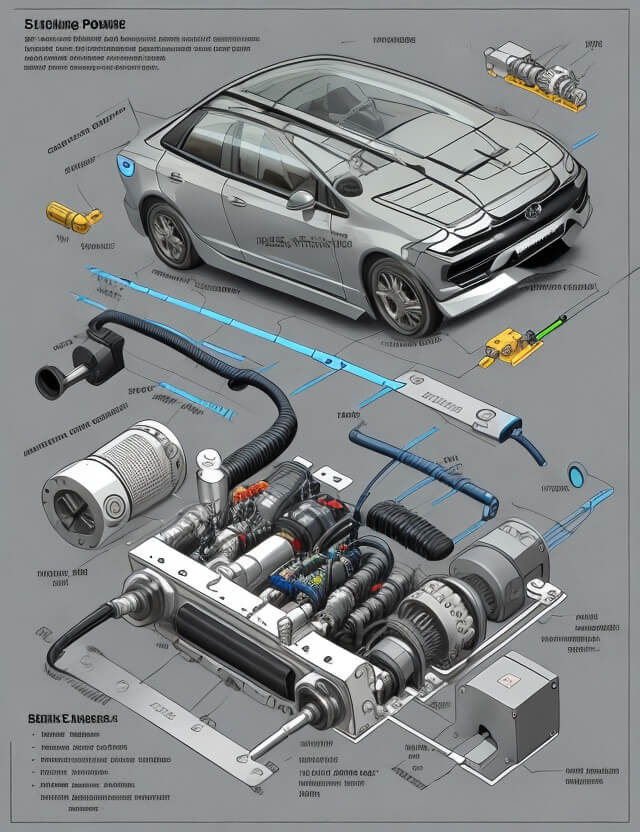

Pneumatic Power Steering System Project

The Pneumatic Power Steering System represents a significant leap in automotive technology, offering a lighter, more efficient alternative to traditional hydraulic systems. By leveraging the power of compressed air, this system aims to reduce driver fatigue and provide a smoother driving experience.

Understanding Pneumatic Power Steering:

Pneumatic power steering systems utilize compressed air to assist in the steering of the vehicle. Unlike the conventional hydraulic power steering that relies on fluid pressure, the pneumatic system uses air pressure, which is controlled through valves and distributed via tubes to deliver the necessary force to the steering linkage.

Components of the System:

- Pneumatic Actuator: The core component that converts air pressure into mechanical motion to assist steering.

- Pneumatics Pipe & Fittings: Channels through which the compressed air is directed and controlled.

- Joints & Mounts: These ensure the secure attachment of the system components to the vehicle’s frame.

- Base Frame: Provides a stable platform for mounting the steering components.

- Connecting Rods: Facilitate the transfer of motion from the pneumatic actuator to the steering mechanism.

- Screws & Bolts: Essential for securely assembling and maintaining the system.

Working Principle:

The pneumatic power steering system operates by taking high-pressure compressed air and transmitting it throughout the system to the pneumatic actuator. As the driver turns the steering wheel, a direction control lever adjusts the flow and pressure of the air, which in turn moves the actuator. This actuator is connected to the vehicle’s wheels via steering linkage, making it easier to steer the vehicle.

Advantages of Pneumatic Power Steering:

- Reduced Weight: Pneumatic systems are typically lighter than their hydraulic counterparts, contributing to overall vehicle weight reduction and improved efficiency.

- Ease of Maintenance: With fewer fluid-related issues and simpler components, pneumatic systems can be easier and less costly to maintain.

- Responsive Handling: Drivers can experience more responsive and smoother steering, enhancing the driving experience, particularly in challenging conditions.

- Environmental Friendliness: As it uses air instead of hydraulic fluid, it eliminates the risk of fluid leaks and is generally cleaner for the environment.

Future Implications:

The integration of pneumatic power steering in modern vehicles could significantly impact automotive design and driver experience. With ongoing advancements in air compression technology and materials science, these systems are set to become more efficient, reliable, and commonplace. As the industry continues to emphasize sustainability and performance, pneumatic power steering systems are well-positioned to play a critical role in the future of transportation.

In order to download the PDF, You must follow on Youtube. Once done, Click on Submit

Follow On YoutubeSubscribed? Click on Confirm

Download Pneumatic Power Steering System Project PDF