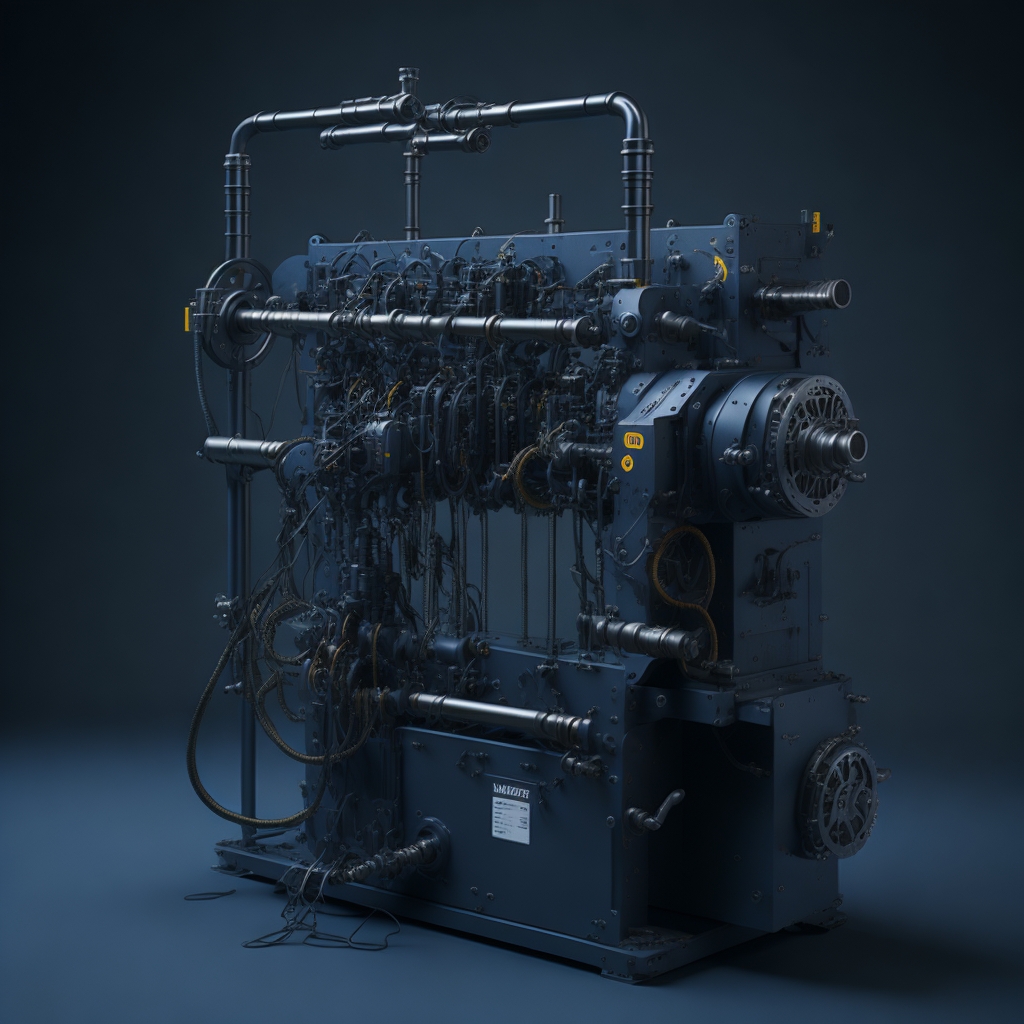

Automated Chain Link Wire Mesh Manufacturing Machine

Introduction

Chain link fences are ubiquitous, serving various purposes from boundary mesh fencing to security barriers. The core element of these fences is the chain link mesh, a zigzag pattern of wire that hooks together to form a durable netting. Traditional methods of creating this mesh can be labor-intensive and time-consuming. Enter the automated chain link machine—a game-changer in the wire mesh manufacturing sector.

The Need for Automation

Creating the zigzag or “link mesh” pattern manually is not only tedious but also less precise. Automated chain link machines offer a fast, efficient, and accurate way to produce high-quality wire mesh. These machines use advanced mechanisms, including a unique bobbin system and a DC motor, to automate the wire-bending process.

Core Components

- DC Motor: Powers the machine and provides the necessary torque for wire bending.

- Shaft and Internal Rod: Attached to the DC motor, these components facilitate the rotation and bending of the wire.

- Slotted Pipe: A hollow tube with a spiral cutout that guides the wire into the desired zigzag pattern.

- Bobbin: Supplies the raw wire to the machine.

- Mesh Wire: The end product, a zigzag-shaped wire ready for linking.

- Supporting Frame and Base Frame: Provide structural integrity to the machine.

- Nuts, Bolts, Mounts, and Joints: Used for assembling and securing the machine components.

How It Works

- Wire Supply: The bobbin feeds raw wire into the machine.

- Rotation: The DC motor powers up, rotating the internal rod inside the slotted pipe.

- Wire Bending: As the rod rotates, the wire is guided through the spiral cutout in the slotted pipe, creating a zigzag pattern.

- Mesh Creation: The zigzag wires are then ready to be linked together to form the final chain link mesh.

Advantages

- Efficiency: Automated machines drastically reduce the time required for mesh production.

- Precision: The machine ensures that each zigzag is uniform, resulting in a more secure and reliable mesh.

- Cost-Effectiveness: Automation reduces labor costs and material wastage.

Conclusion

Automated chain link machines are revolutionizing the wire mesh industry. With their advanced mechanisms and benefits, these machines are indispensable for anyone involved in large-scale wire mesh projects.

In order to download the PDF, You must follow on Youtube. Once done, Click on Submit

Follow On YoutubeSubscribed? Click on Confirm

Download Automated Chain Link Wire Mesh Manufacturing Machine PDF