The 5 Speed Gearbox – Mechanism, Types, and Applications

Introduction

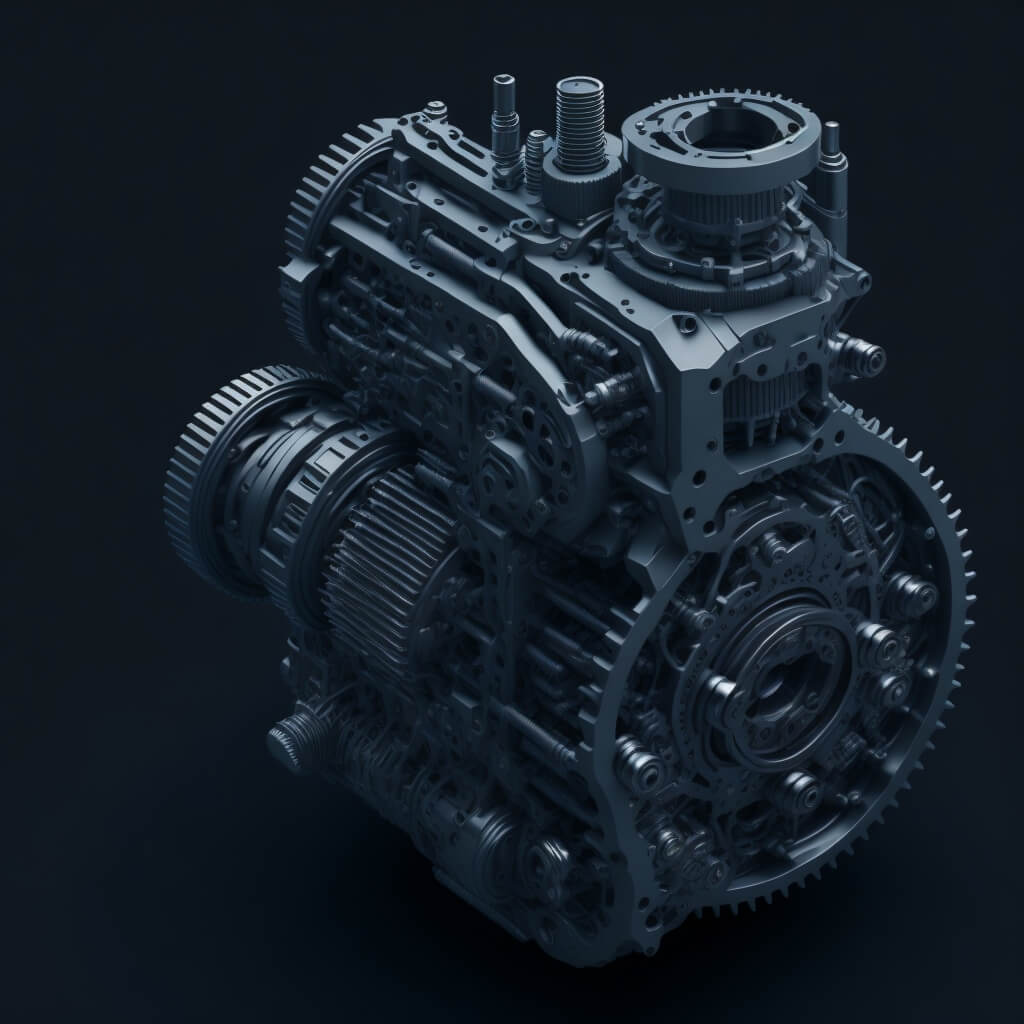

The gearbox is an integral part of many mechanical systems, serving as the bridge between the engine and the machinery it powers. While there are various types of gearboxes, such as helical, planetary, and bevel gears, the focus of this article is on the 5-speed gearbox. This type of gearbox is commonly used in automobiles and industrial machines to offer a balance between speed and torque.

What is a 5-Speed Gearbox?

A 5-speed gearbox is a mechanical system that allows for five different output speeds from a single input speed. It consists of gears of different sizes placed on three different shafts. The topmost shaft is driven by a motor, while the middle shaft acts as an intermediary between the first and third shafts. The middle shaft can be set in six positions: one idle and five active, each corresponding to a different speed.

Gear Arrangements in a 5-Speed Gearbox

The gears in a 5-speed gearbox are arranged in a specific manner to facilitate different speeds. Here’s how the gears mesh in different gears:

- 1st Gear: Gear 1-1 meshes with gear 2-3, and gear 2-5 meshes with gear 3-5.

- 2nd Gear: Gear 1-2 meshes with gear 2-3, and gear 2-4 meshes with gear 3-4.

- 3rd Gear: Gear 1-3 meshes with gear 2-3, and gear 2-3 meshes with gear 3-3.

- 4th Gear: Gear 1-4 meshes with gear 2-3, and gear 2-2 meshes with gear 3-2.

- 5th Gear: Gear 1-5 meshes with gear 2-3, and gear 2-1 meshes with gear 3-1.

Components of a 5-Speed Gearbox

- Gears of different sizes

- Ball bearings

- Shafts

- Wooden or metal frame

- Handle for manual operation

- DC Motor for automatic operation

- Switches and buttons

- Mounts and clamps

- Base and supporting frames

- Screws and bolts

Applications Across Industries

- Automotive: Used in cars for better fuel efficiency and performance.

- Paper Industry: Gearboxes made from various materials like aluminum alloys are used for smooth machine operation.

- Cement Industry: High-torque gearboxes like bevel helical are used for functionalities like speed reduction.

- Steel Industry: Heavy-duty gearboxes like planetary and pinion types are used in sturdy machines.

Conclusion

Understanding the 5-speed gearbox mechanism provides insights into its versatility and efficiency. Whether it’s a high-speed gearbox for fast cars or a high-torque gearbox for industrial machines, the 5-speed gearbox offers a balanced solution for various applications.

In order to download the PDF, You must follow on Youtube. Once done, Click on Submit

Follow On YoutubeSubscribed? Click on Confirm

Download The 5 Speed Gearbox – Mechanism, Types, and Applications PDF