Economics Project on Supply – CBSE 12

SUPPLY

Supply is the quantity of a commodity a firm is willing to sell in a market at a given price in a given period. Supply is a fundamental economic concept that describes the total amount of the specific good or service that is available to a consumer. Supply can be related to the amount available across a range of prices if displayed on the graph. The concept of supply in economics is complex with many mathematical formulas practical applications and contributing factors.

INDIVIDUAL SUPPLY

Individual supply refers to the supply of a commodity an individual seller offers for sale in the market for a stated period for varied prices.

MARKET SUPPLY

The market supply is the total quantity of a good or service all producers are willing to provide at the prevailing set of relative prices during a defined period.

SUPPLY VS STOCK

Supply refers to the quantity that the producer is willing to offer for sale which changes with a change in price whereas stock relates to a particular point in time.

INDIVIDUAL SUPPLY SCHEDULE

An individual supply schedule refers to a tabular statement showing various quantities of a commodity that a producer is willing to sell at various levels of prices during a given period.

| PRICE | QUANTITY |

| (Rs) | SUPPLIED OF GOOD X |

| 1 | 5 |

| 2 | 10 |

| 3 | 15 |

| 4 | 20 |

| 5 | 25 |

As seen in the schedule, the quantity supplied of commodity X increase with the price increase. The producer is willing to sell 5 units of X at a price of Rs1

MARKET SUPPLY SCHEDULE

A market supply schedule refers to a tabular statement showing the various quantities of a commodity that all the producers are willing to at various levels of price during a given period. It is contained by adding all the individual supplies at every level of price.

| PRICE | INDIVIDUAL SUPPLY | MARKET SUPPLY |

| 1 | 5 10 | 5+10=15 |

| 2 | 10 15 | 10+15=25 |

| 3 | 15 20 | 15+20=35 |

| 4 | 20 25 | 25+25=45 |

| 5 | 25 30 | 25+30=55 |

As shown in the table market supply is shown by adding the supply of supplies A and B at different prices.

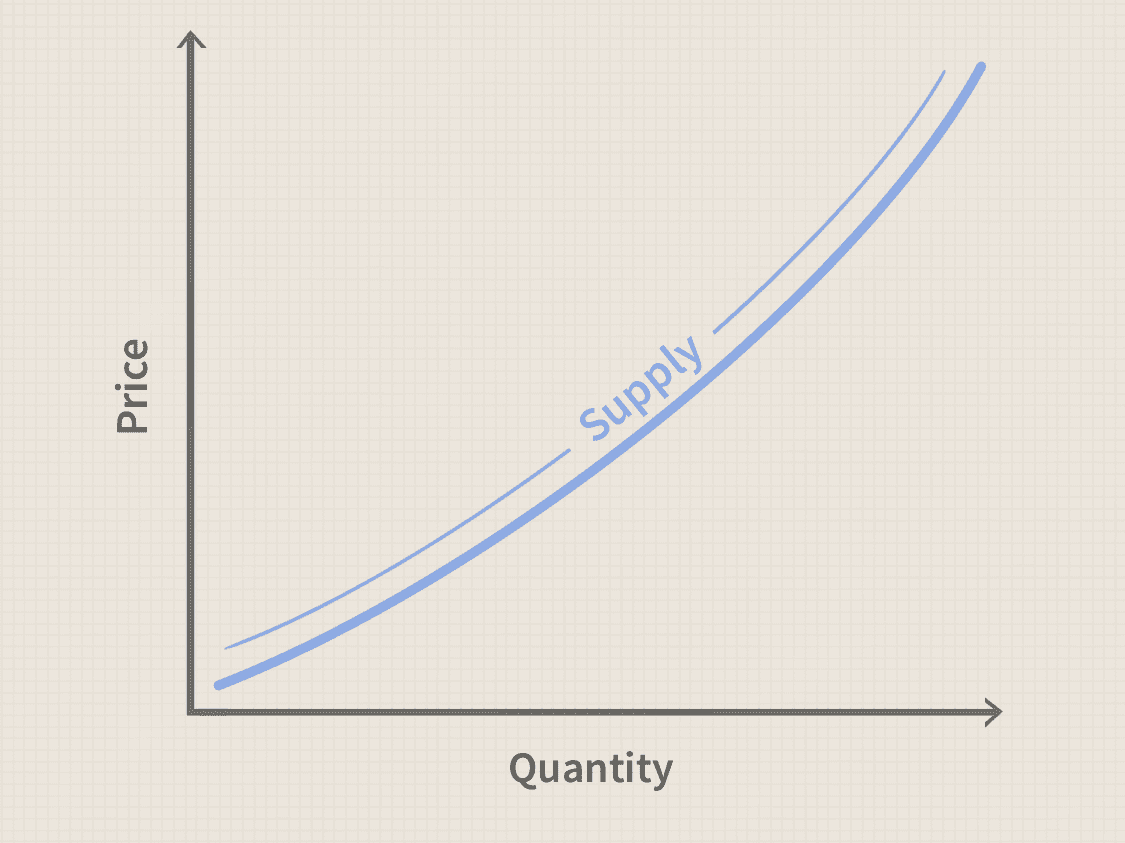

SUPPLY CURVE

INDIVIDUAL SUPPLY CURVE

An individual supply curve refers to a graphical representation of an individual supply schedule curve is obtained by plotting the points. At each possible price, there is a quantity that the firm is willing to sell.

MARKET SUPPLY CURVE

A market supply curve refers to a graphical representation of market supply it is obtained by horizontal summation of individual supply curves. We sum the individual supply curve horizontally to obtain the market supply curve. That is to find the total quantity supplied at any price, we add the individual quantities, which are found on the horizontal axis of the individual supply curve. The market supply curve shows how the total quantity supplied varies as the price & the goods vary; holding constant all the other factors.

FACTORS AFFECTING INDIVIDUAL SUPPLY

- PRICE OF GIVEN COMMODITY

The most important factor determining the supply of a commodity and its price As a general rule price of a commodity and its supply are directly related. It means a prices increase the quantity supplied of the given commodity also rises and vice-versa. - PRICE OF OTHER GOODS

As resources have alternative uses the quantity supplied of a commodity depends not only on price but also on the price of another commodity. Increases in the price of other commodities make them more profitable in comparison to the given commodity. - PRICE OF FACTORS OF PRODUCTION

When the amount payable to the factor of production and cost of inputs increases, the cost of production also increases which decreases the profitability. - STATE OF TECHNOLOGY

Technologies charges influence the supply of a commodity advanced and improved technology reduces the cost of production, which are the profit margin it induces the seller to increase the supply. - GOVERNMENT POLICY

An increase in taxes raises the cost of production and thus reduces the supply due to lower profits margin on the other hand tax concessions and subsidies increase the supply as they make it more profitable for the firm to supply goods. - GOALS/OBJECTIVES OF THE FIRMS

Generally, the supply of a commodity increases only at high prices as it fulfills only profit maximization however with the change in trend. Some firms are willing to supply more even at these prices.

FACTORS AFFECTING MARKET SUPPLY

- NUMBER OF FIRMS IN THE MARKET

When the number of firms in the industry increases market supply also increases due to a large number of products producing that commodity however market supply will decrease if some of the firms start learning the industry due to losses. - FUTURE EXPECTATIONS REGARDING PRICE

If a seller expects a rise in price in near future, the current market supply will decrease to rise the supply in the future of higher prices. - MEANS OF TRANSPORTATION AND COMMUNICATION

Proper infrastructural development, like improvement in the means of transportation and communication, helps to maintain an adequate supply of the commodity.

LAW OF SUPPLY

The Law of supply states that the quantity of a commodity supplied varies directly with its price. Other determined of supply remaining constant. Thus the price of a commodity and the quantity supplied is moved in the same direction. When the price rises quantity supplied also rises and when the price falls. Quantity supply also reduces other things remaining the same. The reason why a firm is willing to sell more quantity of a good at the highest price is found in the law of diminishing returns.

ELASTICITY OF SUPPLY

Define supply function.

It explains the functional relationship between the supply of a commodity and the determinants of supply

Sy = f(Px, Py, Pr, G,T,Tc)

Sx = supply of commodity x

Px = price of the commodity x

Py = price of related goods

Pi = price of inputs

Pg = goals of the firms

Tc = Tax rate

Price elasticity of supply refers to the degree of repossesses of supply of a commodity which references to changes in prices of such commodity.

PERFECTLY ELASTIC SUPPLY

When there is an infant supply at a particular price and the supply becomes zero with a slight fall in price when the supply of such as commodity is said to be perfectly elastic.

| Price(Rs) | Supply (units) |

| 20 | 20 |

| 30 | 20 |

| 40 | 20 |

PERFECTLY INELASTIC SUPPLY

When the supplier does not change with a price change, then the supply for such a commodity is said to be perfectly elastic.

HIGHLY ELASTIC SUPPLY

When the percentage change in quantity supplied is more than the percentage change in price than supply for such a commodity is said to be highly elastic.

| Price(Rs) | Supply (Units) |

| 10 | 100 |

| 15 | 200 |

LESS ELASTIC SUPPLY

When the percentage change in quantity supplied is more than the percentage change in price the supply for such a commodity is said To be less elastic.

UNITARY ELASTIC SUPPLY

When the percentage change in quantity supplied is equal to the percentage change in price then supply for such a commodity is said to be unitary elastic.

CHANGE IN SUPPLY

When there is an increase in supply, demand remains unchanged the supply course of it toward the right from ss to s1 s2

New equilibrium-at determined at E1

Equilibrium price-falls from op to op1

EquEquilibrium quantity sets from OQ to OQ

| Price(Rs) | Supply (Units) |

| 20 | 100 |

| 20 | 150 |

When supply increases to S1 S1 it creates a price on OP this leads to competition among sellers which reduces the price Decrease in price leads to a rise in demand and a fall in supply. This change continues to hill the new equilibrium is established at point E1 equilibrium price falls from OP to OP1 and equilibrium rises from OQ to OQ1

DECREASE IN SUPPLY

When the supply decreases, demand remains unchanged then the supply curve shift to the left from SS to S1 S2When supply decreases to S1 S2, it creates an excess demand at the old equilibrium price of OP this leads to competition among buyers, which raise the price increase in price leads to rising leads to rise in supply and fall in demand. These changes continue till the new equilibrium to established at point E.

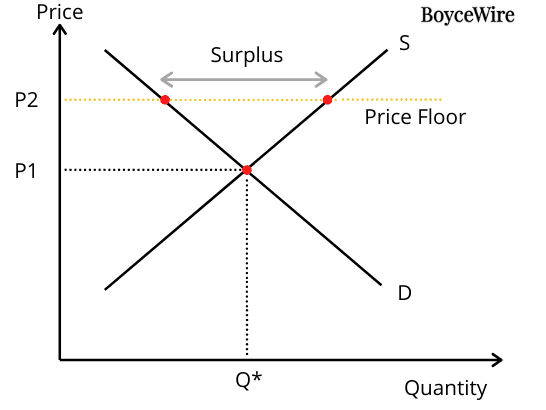

PRICE FLOOR

The government also intervenes in the process of prices determination through the price floor price flow refers to the minimum price ( above the equilibrium price) fixed by the government. which flu producers must be paid for their producers

- When government feels that the price fixed by the forces of demand and supply is not remunerative from the producer’s point of view it fixes prices (known as a price floor) which is more than the equilibrium price.

- Most well-known examples of impossible price flofloorse agriculture price support programs and minimum legislation

- Indian Government maintains a variety of price support programs for various agricultural prproductsike wheat sugarcane etc and the floor is normally set a at level higher than the market-determined price for their goods.

This effect of floor prices can be better understood with the help of the figure

FERTILIZER MARKET

- Demand for food and biofuels constantly increasing.

- With the increase in demand for fertilizer for crop growth.

REASONS

- Population growth.

- Shrinking world grain stock.

- Appetite for corn.

- Growing demand for food especially meat.

PROBLEM

- The fertilizers miners and factories are having trouble keeping up.

- The supply of fertilizer is inelastic.

- The more inelastic supply, the faster prices rise when demand increases.

REASONS FOR INELASTIC

Not enough substitutes.

- Environmental issues.

- Causes depletion of fossil fuel.

- Water pollution due to nitrogen release.

- Dangerous to marine life.

EFFECT OF FERTILIZER ON PRICE

Fertilizers are input into food production as fertilizers price rises.

- The supply of food decreases.

- Loss of food availability.

- Higher food prices.

- Lead to a search for substitutes for fertilizers.

ACKNOWLEDGEMENT

I would like to express my sincere gratitude towards my economics teacher Ms. Kanika Marwaha for her vital support, guidance, and encouragement without which this project would not come forth from my side she helped me in completing the project by giving me ideas, thoughts, and made, this project easy and accurate as well as informative. I wish to thank my parents for their undivided support and interest without which I would be unable to complete my project.

CERTIFICATE

This is to certify that MANSI SINGH of class 12-C has completed her project file under my supervision. She has taken proper care and sincerity in the completion of this project. I certify that this project is up to my expectations and as per the CBSE guidelines

Teacher’s Signature Principal

External Examiner

DOWNLOAD PDF OF THE PROJECT

Password: hscprojects.com

In order to download the PDF, You must follow on Youtube. Once done, Click on Submit

Follow On YoutubeSubscribed? Click on Confirm

Download Economics Project on Supply – CBSE 12 PDF