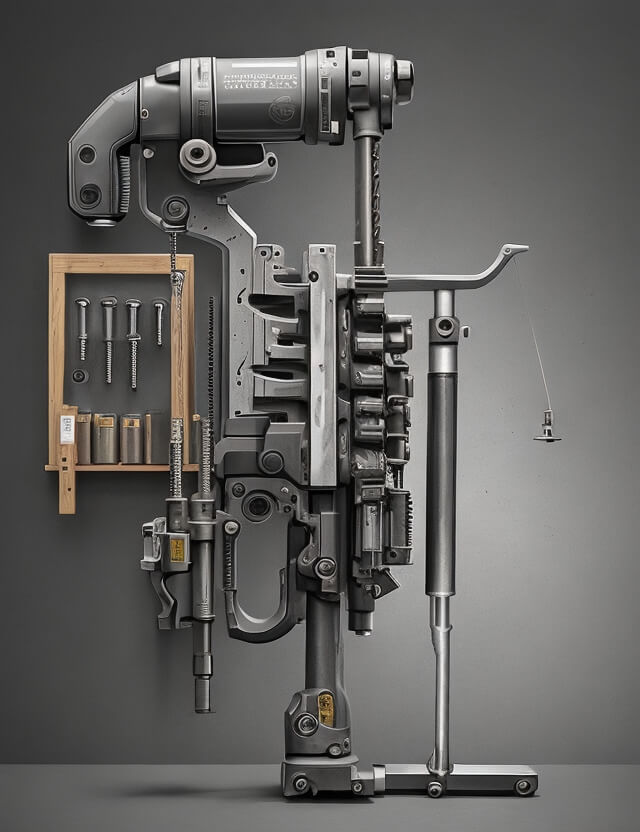

The Arm-Mounted Hammer Drill Machine for Precision and Efficiency

Introduction to the Innovative Hammer Drill Machine

Drilling is a critical task in both fabrication and civil construction, requiring precision and efficiency. Traditional manual drills, while useful, are often slow and demand one hand to operate, reducing work speed. To address this challenge, we introduce the innovative Arm-Mounted Hammer Drill Machine – a game-changer in the drilling process.

Design and Mechanism

The core of this hammer machine drill lies in its arm attachment frame, allowing users to keep one hand free for handling nails or nail plugs. The drill masin is equipped with a high-torque motor, dedicated to the drilling operation. For the hammering action, a secondary geared DC motor is attached, with a shaft connecting to a circular disk, enhancing the drill’s impact.

Enhanced Drilling Efficiency

What sets this hemar masin apart is the connecting rod between the drill bit and the drilling motor. It delivers perpendicular force to the drillbit, boosting drilling efficiency by over 60%. This significant improvement not only speeds up drilling but also reduces the physical effort required.

Precision in Every Hole

A standout feature of our hammer drill is the drill hole depth measurement rod. Adjustable to user preference, it guarantees that each drilled hole is of the exact depth required. This precision is invaluable in ensuring consistent quality in construction and fabrication work.

Advantages of the Arm-Mounted Hammer Drill

- Increased drilling speed.

- Reduced physical effort for the user.

- Consistency in hole depth and accuracy.

- Free hand for handling nails or plugs during drilling.

- Overall efficiency and speed in construction and fabrication tasks.

In conclusion, the Arm-Mounted Hammer Drill Machine is not just a tool, but a leap forward in drilling technology. Its design and functionality make it an indispensable asset for efficient and precise drilling tasks.

Machine Specifications

- Dimensions: 12 x 8 x 35 cm

- Components: Drill Motor, DC Motor, Shaft, Circular Disk, Bearings, Rods, Connecting Rod, Drill Bit, Motor Controller, Arm Bands, Spring, Supporting Frame, Mounts and Joints, Screws and Joints.

Visual Representations

- Front View

- Side View

- 3D Views

In order to download the PDF, You must follow on Youtube. Once done, Click on Submit

Subscribed? Click on Confirm

Download The Arm-Mounted Hammer Drill Machine for Precision and Efficiency PDF